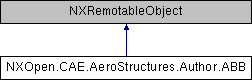

Represents a AeroStruct application building block (ABB) More...

Public Types | |

| enum | Status { Success, Failed } |

| ABB return status More... | |

| enum | EdgeSupportType { SimplySupported, Clamped } |

| Type of support along the edges, the choice is between SimplySupported and Clamped More... | |

| enum | UnloadedEdgeSupportType { ClampedClamped, SimplySupportedClamped, SimplySupportedSimplySupported, FreeClamped, FreeSimplySupported } |

| Type of support along unloaded edges, the choices are: {Clamped-Clamped, Simply Supported-Clamped, Simply Supported-Simply Supported, Free-Clamped, Free-Simply Supported} More... | |

| enum | MaterialBehaviour { Elastic, ElasticPlastic } |

| Material behaivour type, the choices are: {Elastic, Elastic-plastic} More... | |

Public Member Functions | |

| unsafe double | GetUltimateLimitFactor () |

| Ultimate limit factor from the customer default More... | |

| unsafe double | GetIntegerNa () |

| Integer NA value More... | |

| unsafe double | GetPi () |

| PI number More... | |

| unsafe double | GetRealMax () |

| Maximum real number More... | |

| unsafe double | GetRealEpsilon () |

| Real epsilon More... | |

| unsafe double | GetRealNa () |

| Real NA More... | |

| unsafe bool | IsRealNa (double value) |

| Tests if a value is NA More... | |

| unsafe double | GetRealPositiveInfinity () |

| The positive infinity value More... | |

| unsafe bool | IsRealPositiveInfinity (double value) |

| Tests if a value equals positive infinity More... | |

| unsafe double | GetRealNegativeInfinity () |

| The negative infinity value More... | |

| unsafe bool | IsRealNegativeInfinity (double value) |

| Tests if a value equals negative infinity More... | |

| unsafe double | GetMsThreshold () |

| The MS (margin of safety) threshold More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | CurvedMetallicPanelCompressiveBucklingCoefficient (double b, double t, double r, double nu, out double kc) |

| Curves for finding 'kc' the compressive-buckling coefficient for curved sheet panel More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | CurvedMetallicPanelShearBucklingCoefficient (double a, double b, double t, double r, double nu, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bc, out double ks) |

| Curves for finding 'ks' the shear-buckling coefficient for curved sheet panel More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | EquivalentSectionProperties (double[] n, double[] iAi, double[] iEi, double[] iIxxi, out double[] a, out double[] e, out double[] oYcog, out double[] oIxx) |

| Compute equivalent section properties (area, center of gravity, Young's modulus and inertia) of a profile composed of different sub-sections. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | ExtrudedMetallicSubSectionCripplingAllowable (double iFcy, double e, int fe, double b, double t, out double iFcc) |

| Compute Crippling stress allowable for a given segment More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | FlatMetallicPanelBendingBucklingCoefficient (double aOverB, double beta, out double kb) |

| Curves for finding the bending buckling stress coefficient for thin flat plates More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | FlatMetallicPanelCompressiveBucklingCoefficient (double a, double b, NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType bcUnloaded, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bcLoaded, out double kc) |

| Curves for finding 'kc' the compressive-buckling coefficient for rectangular metallic flat plate More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | FlatMetallicPanelShearBucklingCoefficient (double a, double b, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bc, out double ks) |

| Curves for finding 'ks' the shear-buckling coefficient for flat rectangular plate More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | LoadDistributionBoltsConcentricLoads (double[] p, double[] iPsn, int nblcXnbbolt, out double[] oPn) |

| Computes bolt loads for multiple bolt fitting - Concentric load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MaterialFsyEstimation (double iFtyL, double iFtyLT, double iFcyL, double iFcyLT, double iFsu, double iFtuL, double iFtuLT, out double oFsy) |

| Estimation of shear yield stress (Fsy) More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MetallicPanelCompressivePlasticityCurveBc1 (double x, double n, out double z) |

| Metallic panel compressive plasticity curve BC1 Curves for finding critical buckling stress / secant yield stress F0. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MetallicPanelCompressivePlasticityCurveBc2 (double x, double n, out double z) |

| Metallic panel compressive plasticity curve BC2 Curves for finding critical inter-rivet buckling stress (or critical wrinkling stress) / secant yield stress F0. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MetallicPanelCompressivePlasticityCurveBc3 (double x, double n, out double z) |

| Metallic panel compressive plasticity curve BC3 Curves for finding critical buckling stress / secant yield stress F0. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | SecantModulus (double e, double n, double fy, double sigma, out double iEs) |

| Secant modulus Computes the secant modulus from material properties and stress. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | StressFromStrainInPlasticDomain (double strain, double e, double iF02ys, double n, out double sigma) |

| Compute stress from strain with the help of Ramberg-Osgood relationship More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | StressF07 (double iFy, double e, double n, out double f07) |

| Stress F0. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | TangentModulus (double e, double n, double iFy, double sigma, out double oEt) |

| Computes the tangent modulus from material properties and stress. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsAllowable (double allowable, double[] value, out double[] ms) |

| MS allowable. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsBearing (double iFbr, double d, double t, double factor, double[] iPy, double[] iPz, out double[] ms) |

| MS bearing Computes margin of bearing More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsBoltBending (double iMba, double b, double factor, double[] iPy, double[] iPz, out double[] ms) |

| MS bolt bending Computes margin of safety of a bolt under bending load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsBoltCombinedShearTension (double iPTensileAllowable, double[] iPTensileX, double iPShearAllowable, double factor, double[] iPy, double[] iPz, out double[] ms) |

| MS bolt combined shear tension Computes margin of safety of a bolt under shear load and tension load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsBoltCombinedShearTensionBending (double iPTensileAllowable, double[] iPTensileX, double iMAllowable, double b, double factorBend, double[] iPyBend, double[] iPzBend, double iPShearAllowable, double factorShear, double[] iPyShear, double[] iPzShear, out double[] ms) |

| MS bolt combined shear tension bending Computes margin of safety of a bolt under shear, tension and bending load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsBoltShear (double iPShearAllowable, double factor, double[] iPy, double[] iPz, out double[] ms) |

| MS bolt shear Computes margin of safety of a bolt under shear load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsNetSection (double sigmaAllowable, double d, double t, double b, double factor, double[] iPExtracted, out double[] ms) |

| MS Net section Computes margin of net section (due to bolt hole) More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsShearTearOut (double tauAllowable, double d, double t, double b, double factor, double[] iPExtracted, out double[] ms) |

| MS Shear Tear Out Computes margin of shear tear out (due to bolt hole) More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsTsaiHillPlaneStress (double matFcL, double matFcLT, double matFtL, double matFtLT, double matFS, double[] fl, double[] flt, double[] fs, out double[] ms) |

| MS Tsai-Hill Computes margin of safety on the basis of Tsai-Hill failure theory (plane stresses hypothesis) More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsTrescaPlaneStress (double fs, double[] fx, double[] fy, double[] fxy, out double[] ms) |

| MS Tresca. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsMaterialStressAllowable (double allowable, double[] sigma, out double[] ms) |

| MS material stress allowable. More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBuckling (double e, double nu, double b, double t, double k, double eta, double[] sigma, out double[] ms) |

| MS Plate Buckling Computes margin of safety of a metallic plate under buckling load (generic formula) More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingCurvedCompressive (double e, double nu, double n, double a, double b, double t, double r, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma, out double[] ms, out double sigmaAllowable) |

| MS Plate Buckling Curved Compressive Computes margin of safety of a curved metallic rectangular panel under compressive load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingCurvedShear (double e, double nu, double n, double a, double b, double t, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bc, double r, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma, out double[] ms, out double sigmaAllowable) |

| MS Plate Buckling Curved Shear Computes margin of safety of a curved metallic rectangular panel under shear load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingCurvedLongitudinalShearCombined (double e, double nu, double n, double a, double b, double t, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bc, double r, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma, double[] tau, out double[] ms, out double sigmacr, out double taucr) |

| MS Plate Buckling Curved Longitudinal Shear Combined Computes margin of safety of a rectangular curved metallic panel in buckling under combined shear and longitudinal loads More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingFlatBending (double e, double nu, double n, double a, double b, double beta, double t, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma1, double[] sigma2, out double[] ms, out double[] sigmaAllowable) |

| MS Plate Buckling Flat Bending Computes margin of safety of a flat metallic rectangular panel under bending load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingFlatCompressive (double e, double nu, double n, double a, double b, double t, NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType bcUnloaded, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bcLoaded, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma, out double[] ms, out double sigmaAllowable) |

| MS Plate Buckling Flat Compressive Computes margin of safety of a flat metallic rectangular panel under compressive load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingFlatShear (double e, double nu, double n, double a, double b, double t, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bc, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma, out double[] ms, out double sigmaAllowable) |

| MS Plate Buckling Flat Shear Computes margin of safety of a flat metallic rectangular panel under shear load More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingFlatLongitudinalBendingCombined (double e, double nu, double n, double a, double b, double t, NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType bcUnloaded, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bcLoaded, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma1, double[] sigma2, out double[] ms, out double sigmacr, out double sigmabcr) |

| MS Plate Buckling Flat Longitudinal Bending Combined Computes margin of safety of a rectangular flat metallic panel in buckling under combined bending and longitudinal loads More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingFlatLongitudinalShearCombined (double e, double nu, double n, double a, double b, double t, NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType bcUnloaded, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bcLoaded, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma, double[] tau, out double[] ms, out double sigmacr, out double taucr) |

| MS Plate Buckling Flat Longitudinal Shear Combined Computes margin of safety of a rectangular flat metallic panel in buckling under combined shear and longitudinal loads More... | |

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status | MsPlateBucklingFlatShearBendingCombined (double e, double nu, double n, double a, double b, double t, NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType bcUnloaded, NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType bcLoaded, NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour behaviour, double[] sigma1, double[] sigma2, double[] tau, out double[] ms, out double sigmabcr, out double taucr) |

| MS Plate Buckling Flat Shear Bending Combined Computes margin of safety of a rectangular flat metallic panel in buckling under combined bending and shear loads More... | |

Static Public Member Functions | |

| static ABB | GetABB (NXOpen.Session owner) |

| Returns the ABB object for the running session which serves as the 'gateway' class for the application API. More... | |

Properties | |

| Tag | Tag [get] |

| Returns the tag of this object. More... | |

Detailed Description

Represents a AeroStruct application building block (ABB)

To obtain an instance of this class, refer to NXOpen.Session

Created in NX12.0.0

Member Enumeration Documentation

Type of support along unloaded edges, the choices are: {Clamped-Clamped, Simply Supported-Clamped, Simply Supported-Simply Supported, Free-Clamped, Free-Simply Supported}

Member Function Documentation

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.CurvedMetallicPanelCompressiveBucklingCoefficient | ( | double | b, |

| double | t, | ||

| double | r, | ||

| double | nu, | ||

| out double | kc | ||

| ) |

Curves for finding 'kc' the compressive-buckling coefficient for curved sheet panel

This curve is extracted from Bruhn manual, figure C9.1 Used for finding 'kc' the compressive-buckling coefficient for curved sheet panel, with simply-supported edges.

Input b dimension in radial axis t thickness r radius nu Poisson coefficient Output kc compressive-buckling coefficient Returns Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

b Dimension in radial axis t Panel thickness r Panel radius nu Material Poisson coefficient kc Compressive-buckling coefficient

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.CurvedMetallicPanelShearBucklingCoefficient | ( | double | a, |

| double | b, | ||

| double | t, | ||

| double | r, | ||

| double | nu, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bc, | ||

| out double | ks | ||

| ) |

Curves for finding 'ks' the shear-buckling coefficient for curved sheet panel

These curves are extracted from Bruhn manual, figures C9.

2 to C9.5 Used for finding 'ks' the shear-buckling coefficient for curved sheet panel, with simply-supported or clamped edges.

Input a Dimension in longitudinal axis b Dimension in radial axis t Thickness r Radius nu Poisson coefficient BC Type of support along the edges, the choice is between SimplySupported and Clamped Output ks Shear-buckling coefficient Returns False if input values are out of bounds

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

a Dimension in longitudinal axis b Dimension in radial axis t Thickness r Radius nu Poisson coefficient bc Type of support along the edges ks Compressive-buckling coefficient

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.EquivalentSectionProperties | ( | double[] | n, |

| double[] | iAi, | ||

| double[] | iEi, | ||

| double[] | iIxxi, | ||

| out double[] | a, | ||

| out double[] | e, | ||

| out double[] | oYcog, | ||

| out double[] | oIxx | ||

| ) |

Compute equivalent section properties (area, center of gravity, Young's modulus and inertia) of a profile composed of different sub-sections.

Input n Number of sub-sections that compose the section Ai Areas of sub-sections Ycogi Center of gravity of sub-sections in Y direction Ei Young's modulus of sub-sections Ixxi Moments of inertia (Quadratic moments) of sub-sections around XX (expressed at the center of gravity of each sub-section) Output A Area of the equivalent section (sum of all sub-sections) E Young's modulus of the equivalent section Ycog Center of gravity of the equivalent section in Y direction Ixx Moment of inertia of the equivalent section around XX (expressed at the center of gravity of the equivalent section)

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

n Number of sub-sections that compose the section iAi Areas of sub-sections iEi Young's modulus of sub-sections iIxxi Moments of inertia (Quadratic moments) of sub-sections around XX (expressed at the center of gravity of each sub-section) a Area of the equivalent section (sum of all sub-sections) e Young's modulus of the equivalent section oYcog Center of gravity of the equivalent section in Y direction oIxx Moment of inertia of the equivalent section around XX (expressed at the center of gravity of the equivalent section)

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.ExtrudedMetallicSubSectionCripplingAllowable | ( | double | iFcy, |

| double | e, | ||

| int | fe, | ||

| double | b, | ||

| double | t, | ||

| out double | iFcc | ||

| ) |

Compute Crippling stress allowable for a given segment

Crippling curves for a sub-section (also called a segment) of extruded metallic profiles.

The computed value is 'Fcc'. 'Fcc' is thresholded by 'Fcy', to avoid plasticity of material. Segment's width ('b') is assumed to be greater than its thickness ('t').

Input Fcy Compressive yield allowable stress E Young's modulus FE Segment's number of free edges b Segment's width t Segment's thickness Output Fcc Equivalent stress allowable Returns Computation status

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

iFcy Compressive yield allowable stress e Young's modulus fe Segment's number of free edges b Segment's width t Segment's thickness iFcc Equivalent stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.FlatMetallicPanelBendingBucklingCoefficient | ( | double | aOverB, |

| double | beta, | ||

| out double | kb | ||

| ) |

Curves for finding the bending buckling stress coefficient for thin flat plates

Used for finding 'kb' the bending buckling stress coefficient as a function of: * 'a/b', the panel length ratio * 'a' is the unloaded edge length * 'b' is the loaded edge length * 'beta', is the factor which, divided to b, gives the edge length in compression (while the remaining edge length is in tension).

Input a_over_b Panel length ratio beta loading length ratio Output kb bending buckling stress coefficient Returns False if input values are out of bounds

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

aOverB Panel length ratio beta Loading length ratio kb Bending buckling stress coefficient

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.FlatMetallicPanelCompressiveBucklingCoefficient | ( | double | a, |

| double | b, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType | bcUnloaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bcLoaded, | ||

| out double | kc | ||

| ) |

Curves for finding 'kc' the compressive-buckling coefficient for rectangular metallic flat plate

Used for finding 'kc' the compressive-buckling coefficient for rectangular metallic flat plate, as a function of edge lengths and edge boundary conditions

Input a Unloaded edge length b Loaded edge length BC_Unloaded Type of support along unloaded edges {Clamped-Clamped, Simply Supported-Clamped, Simply Supported-Simply Supported, Free-Clamped, Free-Simply Supported} BC_Loaded Type of support along loaded edges {Clamped or Simply Supported} Output kc Compressive buckling coefficient Returns Computation status

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

a Unloaded edge length b Loaded edge length bcUnloaded Type of support along unloaded edges bcLoaded Type of support along loaded edges kc Compressive buckling coefficient

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.FlatMetallicPanelShearBucklingCoefficient | ( | double | a, |

| double | b, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bc, | ||

| out double | ks | ||

| ) |

Curves for finding 'ks' the shear-buckling coefficient for flat rectangular plate

These curves are inspired by Bruhn manual. Used for finding 'ks' the shear-buckling coefficient for flat rectangular plate, as a function of edge lengths and boundary conditions

Input a Longer plate dimension b Shorter plate dimension BC Type of support along the edges {Simply Supported or Clamped} Output ks Shear-buckling coefficient Returns Computation status

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

a Longer plate dimension b Shorter plate dimension bc Type of support along the edges ks Shear-buckling coefficient

- Returns

|

static |

Returns the ABB object for the running session which serves as the 'gateway' class for the application API.

References to all other objects in this API are obtained either directly or indirectly via methods and properties on this class. Platform Session should be initialized using 'GetSession' method from NXOpen API prior to this call.

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetIntegerNa | ( | ) |

Integer NA value

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetMsThreshold | ( | ) |

The MS (margin of safety) threshold

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetPi | ( | ) |

PI number

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetRealEpsilon | ( | ) |

Real epsilon

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetRealMax | ( | ) |

Maximum real number

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetRealNa | ( | ) |

Real NA

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetRealNegativeInfinity | ( | ) |

The negative infinity value

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetRealPositiveInfinity | ( | ) |

The positive infinity value

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe double NXOpen.CAE.AeroStructures.Author.ABB.GetUltimateLimitFactor | ( | ) |

Ultimate limit factor from the customer default

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Returns

| unsafe bool NXOpen.CAE.AeroStructures.Author.ABB.IsRealNa | ( | double | value | ) |

Tests if a value is NA

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

value

- Returns

| unsafe bool NXOpen.CAE.AeroStructures.Author.ABB.IsRealNegativeInfinity | ( | double | value | ) |

Tests if a value equals negative infinity

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

value

- Returns

| unsafe bool NXOpen.CAE.AeroStructures.Author.ABB.IsRealPositiveInfinity | ( | double | value | ) |

Tests if a value equals positive infinity

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

value

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.LoadDistributionBoltsConcentricLoads | ( | double[] | p, |

| double[] | iPsn, | ||

| int | nblcXnbbolt, | ||

| out double[] | oPn | ||

| ) |

Computes bolt loads for multiple bolt fitting - Concentric load

Formula Pn = P * (Psn / SUM(Psn)) where: * 'P' is the load acting on the fitting * 'Psn' is the allowable strength of bolt n * 'Pn' is the shear load on bolt n

Input nblc Number of load cases P Load acting on fitting (nblc) nbbolt Number of bolts Psn Allowable shear strength of bolt (nbbolt) Output Pn Shear load on bolt (nblc x nbbolt) Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

p Load acting on fitting (nblc) iPsn Allowable shear strength of bolt (nbbolt) nblcXnbbolt oPn Shear load on bolt (nblc x nbbolt)

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MaterialFsyEstimation | ( | double | iFtyL, |

| double | iFtyLT, | ||

| double | iFcyL, | ||

| double | iFcyLT, | ||

| double | iFsu, | ||

| double | iFtuL, | ||

| double | iFtuLT, | ||

| out double | oFsy | ||

| ) |

Estimation of shear yield stress (Fsy)

Shear yield stress allowable ('Fsy') is estimated on the basis of the following formula: 'Fsy=( FtyL + FtyLT + FcyL + FcyLT ) / 4 * ( 2 * Fsu)/( FtuL + FtuLT )' where: * 'FtyL' is the tensile yield stress under longitudinal direction * 'FtyLT' is the tensile yield stress under long transverse direction * 'FcyL' is the compressive yield stress under longitudinal direction * 'FcyLT' is the compressive yield stress under long transverse direction * 'Fsu' is the shear ultimate stress * 'FtuL' is the tensile ultimate stress under longitudinal direction * 'FtuLT' is the tensile ultimate stress under long transverse direction

Input FtyL Tensile yield stress, longitudinal direction FtyLT Tensile yield stress, long transverse direction FcyL Compressive yield stress, longitudinal direction FcyLT Compressive yield stress, long transverse direction Fsu Shear ultimate stress FtuL Tensile ultimate stress, longitudinal direction FtuLT Tensile ultimate stress, long transverse direction Output Fsy Shear yield stress Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

iFtyL Tensile yield stress, longitudinal direction iFtyLT Tensile yield stress, long transverse direction iFcyL Compressive yield stress, longitudinal direction iFcyLT Compressive yield stress, long transverse direction iFsu Shear ultimate stress iFtuL Tensile ultimate stress, longitudinal direction iFtuLT Tensile ultimate stress, long transverse direction oFsy Shear yield stress

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MetallicPanelCompressivePlasticityCurveBc1 | ( | double | x, |

| double | n, | ||

| out double | z | ||

| ) |

Metallic panel compressive plasticity curve BC1 Curves for finding critical buckling stress / secant yield stress F0.

7

Used for finding 'sigma_cr' the inelastic buckling strength of metallic flat rectangular plate in compression. The Boundary Condition for the unloaded edges is Simply Supported-Free. It computes: * 'sigma_cr /sigma_0.7' as a function of '(kc * pi^2E) / (12 * (1-nu^2) * sigma_0.7)(t/b)^2' and 'n' where * 'sigma_cr' is the critical stress allowable * 'sigma_0.7' is the [stress for secant modulus equal to 70% of Young modulus] * 'kc' is the buckling coefficient, computed in Figure FlatMetallicPanelCompressiveBucklingCoefficient * 'E' is the Young's modulus * 'nu' is the Poisson coefficient * 't' is the plate thickness * 'b' is the loaded edge length * 'n' is the Ramberg-Osgood parameter

Input X Critical buckling stress (elastic) / secant yield stress F0.7 n Ramberg-Osgood parameter Output Z Critical buckling stress (including plasticity) / secant yield stress F0.7 Returns Status of the computation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

x Critical buckling stress (elastic) / secant yield stress F0.7 n Ramberg-Osgood parameter z Critical buckling stress (including plasticity) / secant yield stress F0.7

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MetallicPanelCompressivePlasticityCurveBc2 | ( | double | x, |

| double | n, | ||

| out double | z | ||

| ) |

Metallic panel compressive plasticity curve BC2 Curves for finding critical inter-rivet buckling stress (or critical wrinkling stress) / secant yield stress F0.

7

Used for finding 'Fir' or 'Fw'. It computes either: * 'Fir /F0.7' as a function of '(C * pi^2E)/(12 * (1-nu^2) * F0.7)(ts/p)^2' and 'n' where * 'Fir' is the Inter-Rivet Buckling stress allowable (with plasticity) * 'F0.7' is the [stress for secant modulus equal to 70% of Young modulus] * 'C' is the end fixity coefficient * 'E' is the Young's modulus * 'nu' is the Poisson coefficient * 'ts' is the thickness of the sheet * 'p' is the rivet spacing * 'n' is the Ramberg-Osgood parameter

Or: * 'Fw /F0.7' as a function of '(kw * pi^2E)/(12 * (1-nu^2) * F0.7)(ts/bs)^2' and 'n' where * 'Fw' is the wrinkling stress allowable * 'kw' is the wrinkling failing stress coefficient * 'ts' is the thickness of the sheet * 'bs' is the stiffener spacing * 'n' is the Ramberg-Osgood parameter

Input X Critical buckling stress (elastic) / secant yield stress F0.7 n Ramberg-Osgood parameter Output Z Critical buckling/wrinkling stress (including plasticity) / secant yield stress F0.7 Returns Status of the computation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

x Critical buckling stress (elastic) / secant yield stress F0.7 n Ramberg-Osgood parameter z Critical buckling/wrinkling stress (including plasticity) / secant yield stress F0.7

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MetallicPanelCompressivePlasticityCurveBc3 | ( | double | x, |

| double | n, | ||

| out double | z | ||

| ) |

Metallic panel compressive plasticity curve BC3 Curves for finding critical buckling stress / secant yield stress F0.

7

Used for finding 'sigma_cr' the inelastic buckling strength of metallic cylinder in compression.

It computes: * 'sigma_cr /sigma_0.7' as a function of '(kc * pi^2E)/(12 * (1-nu^2) * sigma_0.7)(t/b)^2' and 'n' where * 'sigma_cr' is the critical stress allowable * 'sigma_0.7' is the [stress for secant modulus equal to 70% of Young's modulus] * 'kc' is the buckling coefficient, computed in Figure FlatMetallicPanelCompressiveBucklingCoefficient * 'E' is the Young's modulus * 'nu' is the Poisson coefficient * 't' is the plate thickness * 'b' is the loaded edge length * 'n' is the Ramberg-Osgood parameter

Input X Critical buckling stress (elastic) / secant yield stress F0.7 n Ramberg-Osgood parameter Output Z Critical buckling stress (including plasticity) / secant yield stress F0.7 Returns Status of the computation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

x Critical buckling stress (elastic) / secant yield stress F0.7 n Ramberg-Osgood parameter z Critical buckling stress (including plasticity) / secant yield stress F0.7

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsAllowable | ( | double | allowable, |

| double[] | value, | ||

| out double[] | ms | ||

| ) |

MS allowable.

Computes margin of safety based on an allowable

The formula is MS = Allowable / Value - 1

where: * 'Allowable' is the manual input * 'Value' is the value coming from load extractor * 'MS' is the margin of safety

Input Allowable Manual input Value(nblc) Value coming from load extractor Output MS(nblc) Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

allowable Manual input value Value coming from load extractor ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsBearing | ( | double | iFbr, |

| double | d, | ||

| double | t, | ||

| double | factor, | ||

| double[] | iPy, | ||

| double[] | iPz, | ||

| out double[] | ms | ||

| ) |

MS bearing Computes margin of bearing

The formula is 'MS = PBearingAllowable / P - 1'

where * 'PBearingAllowable' is the bearing load allowable ('PBearingAllowable = Fbr * D * t') 'Fbr' is the bearing stress allowable 'D' is the d iameter 't' is the thickness * 'P' is the bearing load (P = FactorLoad * PExtracted) 'FactorLoad' is the ratio of load between extracted load 'PExtracted' and 'P' 'PExtracted' is the extracted load ('PExtracted = sqrt( Py ^ 2 + Pz ^ 2 )') 'Py' is the shear load in Y direction 'Pz' is the shear load in Z direction

Input Fbr Bearing stress allowable D Diameter t Thickness Factor Load factor Py Shear load Y direction Pz Shear load Z direction Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

iFbr Bearing stress allowable d Diameter t Thickness factor Load factor iPy Shear load Y direction iPz Shear load Z direction ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsBoltBending | ( | double | iMba, |

| double | b, | ||

| double | factor, | ||

| double[] | iPy, | ||

| double[] | iPz, | ||

| out double[] | ms | ||

| ) |

MS bolt bending Computes margin of safety of a bolt under bending load

The formula is 'MS = MBendingAllowable / M - 1'

where * 'MBendingAllowable' is the bending moment allowable of the bolt. * 'M' is the bending moment applied to the bolt. ('M = b * P') where: 'b' is the arm 'P' is the load ('P = FactorLoad * PExtracted') 'FactorLoad' is the ratio of load between extracted load 'PExtracted' and 'P' 'PExtracted' is the extracted load ('PExtracted = sqrt(Py^2 + Pz^2)') 'Py' is the shear load in Y direction 'Pz' is the shear load in Z direction Input Mba Bending moment allowable of bolt b Arm Factor Load factor Py Shear load Y direction Pz Shear load Z direction Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

iMba Bending moment allowable of bolt b Arm factor Load factor iPy Shear load Y direction iPz Shear load Z direction ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsBoltCombinedShearTension | ( | double | iPTensileAllowable, |

| double[] | iPTensileX, | ||

| double | iPShearAllowable, | ||

| double | factor, | ||

| double[] | iPy, | ||

| double[] | iPz, | ||

| out double[] | ms | ||

| ) |

MS bolt combined shear tension Computes margin of safety of a bolt under shear load and tension load

The formula is 'MS = 1 / sqrt( Rt ^ 2 + Rs ^ 3 ) - 1' where * Rt = PTensileX/PTensileAllowable * Rs = PShear/PShearAllowable *'PTensileAllowable' is the tensile load allowable of the bolt * 'PTensileX' is the tensile load applied on the fastener * 'PShearAllowable' is the single shear load allowable of the bolt * 'Pshear' is the shearing load applied through the shear area. PShear = FactorLoad * PExtracted * 'FactorLoad' is the ratio of load between extracted load PExtracted and PShear * 'PExtracted' is the extracted load ('PExtracted = sqrt(Py^2 + Pz^2)') * 'Py' is the shear load in Y direction * 'Pz' is the shear load in Z direction

Input nblc Number of loadcases PTensileAllowable Tensile load allowable PTensileX(nblc) Tensile load PShearAllowable Single shear load allowable Factor Load factor Py(nblc) Shear load Y direction Pz(nblc) Shear load Z direction Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

iPTensileAllowable Tensile load allowable iPTensileX Tensile load iPShearAllowable Single shear load allowable factor Load factor iPy Shear load Y direction iPz Shear load Z direction ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsBoltCombinedShearTensionBending | ( | double | iPTensileAllowable, |

| double[] | iPTensileX, | ||

| double | iMAllowable, | ||

| double | b, | ||

| double | factorBend, | ||

| double[] | iPyBend, | ||

| double[] | iPzBend, | ||

| double | iPShearAllowable, | ||

| double | factorShear, | ||

| double[] | iPyShear, | ||

| double[] | iPzShear, | ||

| out double[] | ms | ||

| ) |

MS bolt combined shear tension bending Computes margin of safety of a bolt under shear, tension and bending load

The formula is MS = 1 / sqrt ( ( Rt + Rb ) ^ 2 + Rs ^ 3 ) - 1 where * Rt = PTensileX / PTensileAllowable * Rb = M / MAllowable * Rs = PShear / PShearAllowable

Tensile data * 'PTensileAllowable' is the tensile load allowable of the bolt * 'PTensileX' is the tensile load applied on the fastener

Bending data * 'MAllowable' is the bending moment allowable of the bolt * 'M' is the bending moment applied to the bolt. M = b * PBend PBend = FactorLoadBend * sqrt(PyBend^2 + PzBend^2) * 'b' is the arm * 'FactorLoadBend' is the load factor for bending * 'PyBend' is the bending load in Y direction * 'PzBend' is the shear load in Z direction

Shear data * 'PShearAllowable' is the single shear load allowable of the bolt * 'PShear' is the shearing load applied through the shear area. PShear = FactorLoadShear * sqrt(PyShear^2 + PzShear^2) * 'FactorLoadShear' is the load factor for shearing * 'PyShear' is the shear load in Y direction * 'PzShear' is the shear load in Z direction

Input nblc Number of loadcases PTensileAllowable Tensile load allowable PTensileX(nblc) Tensile load

MAllowable Bending moment allowable of bolt b Arm FactorBend Load factor for bending PyBend(nblc) Bending load Y direction PzBend(nblc) Bending load Z direction

PShearAllowable Single shear load allowable FactorShear Load factor for shear PyShear(nblc) Shear load Y direction PzShear(nblc) Shear load Z direction Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

iPTensileAllowable Tensile load allowable iPTensileX Tensile load iMAllowable Bending moment allowable of bolt b Arm factorBend Bending load factor iPyBend Bending load Y direction iPzBend Bending load Z direction iPShearAllowable Single shear load allowable factorShear Shear load factor iPyShear Shear load Y direction iPzShear Shear load Z direction ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsBoltShear | ( | double | iPShearAllowable, |

| double | factor, | ||

| double[] | iPy, | ||

| double[] | iPz, | ||

| out double[] | ms | ||

| ) |

MS bolt shear Computes margin of safety of a bolt under shear load

The formula is MS = PShearAllowable / P - 1 where * 'PShearAllowable' is the single shear load allowable of the bolt * 'P' is the shearing load applied through the shear area. P = FactorLoad * PExtracted * 'FactorLoad' is the ratio of load between extracted load 'PExtracted' and 'P' * 'PExtracted' is the extracted load ('PExtracted = sqrt(Py^2 + Pz^2)') * 'Py' is the shear load in Y direction * 'Pz' is the shear load in Z direction

Input nblc Number of loadcases PShearAllowable Single shear load allowable Factor Load factor Py(nblc) Shear load Y direction Pz(nblc) Shear load Z direction Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

iPShearAllowable Single shear load allowable factor Shear load factor iPy Shear load Y direction iPz Shear load Z direction ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsMaterialStressAllowable | ( | double | allowable, |

| double[] | sigma, | ||

| out double[] | ms | ||

| ) |

MS material stress allowable.

Computes margin of safety based on a material allowable

The formula is MS = StressAllowable / Stress - 1

where: * 'Allowable' is the material stress allowable * 'Stress' is the stress * 'MS' is the margin of safety

Input Allowable Material stress allowable sigma(nblc) Stress Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

allowable Material stress allowable sigma Stress ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsNetSection | ( | double | sigmaAllowable, |

| double | d, | ||

| double | t, | ||

| double | b, | ||

| double | factor, | ||

| double[] | iPExtracted, | ||

| out double[] | ms | ||

| ) |

MS Net section Computes margin of net section (due to bolt hole)

The formula is MS = PNetSectionAllowable / P - 1

where: * 'PNetSectionAllowable' is the net section load allowable. PNetSectionAllowable = SigmaAllowable * t * ( b - D ) * 'SigmaAllowable' is the material stress allowable. For instance, it could be Ftu * 'D' is the hole diameter * 't' is the thickness * 'b' is the width of the net section

* 'P' is the load. P = FactorLoad * PExtracted * 'FactorLoad' is the ratio of load between extracted load 'PExtracted' and 'P' * 'PExtracted' is the extracted load

* 'MS' is the margin of safety

Input SigmaAllowable Material stress allowable D Diameter t Thickness b Width Factor Load factor PExtracted(nblc) Axial load (extracted) Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

sigmaAllowable Material stress allowable d Diameter t Thickness b Width factor Load factor iPExtracted Axial load (extracted) ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBuckling | ( | double | e, |

| double | nu, | ||

| double | b, | ||

| double | t, | ||

| double | k, | ||

| double | eta, | ||

| double[] | sigma, | ||

| out double[] | ms | ||

| ) |

MS Plate Buckling Computes margin of safety of a metallic plate under buckling load (generic formula)

The formula is MS = Allowable / Stress - 1

where: * 'Allowable' is the compressive buckling stress allowable * 'Stress' is the stress * 'MS' is the margin of safety

Allowable = eta * PI^2*k*E/(12*(1-nu^2)) * (t/b)^2 where * 'k' is the buckling coefficient * 'E' is the Young modulus * 'nu' is the elastic Poisson coefficient * 't' is the panel thickness * 'b' is the panel dimension * 'eta' is the plasticity reduction factor: SigmaAllowablePlastic = eta*SigmaAllowableElastic

Input E Young modulus nu Elastic Poisson coefficient b Panel dimension t Panel thickness k Buckling coefficient eta Plasticity reduction factor nblc Number of load cases sigma Stress coming from load extraction Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient b Panel dimension t Panel thickness k Buckling coefficient eta Plasticity reduction factor sigma Stress coming from load extraction ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingCurvedCompressive | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | t, | ||

| double | r, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma, | ||

| out double[] | ms, | ||

| out double | sigmaAllowable | ||

| ) |

MS Plate Buckling Curved Compressive Computes margin of safety of a curved metallic rectangular panel under compressive load

The formula is MS = Allowable / |Stress| - 1

where: * 'Allowable' is the compressive buckling stress allowable * 'Stress' is the compressive stress (MS is not calculated in case of tensile stress), * 'MS' is the margin of safety

Allowable = eta * PI^2*kc*E/(12*(1-nu^2)) * (t/c)^2 where * 'kc' is the buckling coefficient * 'E' is the Young modulus * 'nu' is the elastic Poisson coefficient * 't' is the panel thickness * 'c' is the shorter panel dimension c = min(a,b) * 'eta' is the plasticity reduction factor: SigmaAllowablePlastic = eta*SigmaAllowableElastic * eta = 1 if material is considered as elastic (Material behaviour = Elastic) * eta is obtain from following charts if material is considered as elastic-plastic (Material behaviour = Elastic-Plastic):

SigmaAllowablePlastic/Sigma0.7 = f(SigmaAllowableElastic/Sigma0.7)

MetallicPanelCompressivePlasticityCurveBC3 with Sigma0.7 is the stress for secant modulus equal to 70% of Young modulus Input E Young modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness r Panel radius of curvature behaviour Material behaviour nblc Number of load cases sigma Stress coming from load extraction Output sigmaAllowable Stress allowable MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness r Panel radius of curvature behaviour Material behaviour sigma Stress coming from load extraction ms Margin of safety sigmaAllowable Stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingCurvedLongitudinalShearCombined | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | t, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bc, | ||

| double | r, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma, | ||

| double[] | tau, | ||

| out double[] | ms, | ||

| out double | sigmacr, | ||

| out double | taucr | ||

| ) |

MS Plate Buckling Curved Longitudinal Shear Combined Computes margin of safety of a rectangular curved metallic panel in buckling under combined shear and longitudinal loads

Under compressive loads

Under compressive and shear loads, the interaction equation is: RL^2 + RS^2 = 1.0

The Margin Safety is given by the following formula:

MS=2/(RL+sqrt(RL^2+4*RS^2))-1 where:

* RL = sigma / sigma_cr is the stress ratio due to longitudinal stress, with: * sigma is the given longitudinal stress * sigma_cr is the compression stress allowable for buckling (sigma_cr < 0, as consequence RL < 0 in tension)

* RS = tau / tau_cr is the stress ratio due to shear stress with: * tau is the given shear stress * tau_cr is the shear stress allowable for buckling (tau and tau_cr always positive)

Under tensile loads

Under tensile and shear loads, the interaction equation is: 1/2 * RL + RS = 1.0

The Margin Safety is given by the following formula: MS = (2 - RL) / ( 2 * RS ) - 1

The panel edges are either clamped or simply supported. Plasticity is not taken into account.

Input E Young modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness BC Type of support along edges ('Clamped' or 'Simply Supported') r Panel radius of curvature behaviour Material behaviour ('Elastic' or 'Elastic-Plastic') nblc Number of load cases sigma Stress XX coming from load extraction tau Stress YY coming from load extraction Output MS Margin of safety sigmacr Compressive stress allowable taucr Shear stress allowable

Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness bc Type of support along the edges r Panel radius of curvature behaviour Material behaviour sigma Stress XX coming from load extraction tau Stress YY coming from load extraction ms Margin of safety sigmacr Compressive stress allowable taucr Shear stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingCurvedShear | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | t, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bc, | ||

| double | r, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma, | ||

| out double[] | ms, | ||

| out double | sigmaAllowable | ||

| ) |

MS Plate Buckling Curved Shear Computes margin of safety of a curved metallic rectangular panel under shear load

The formula is MS = Allowable / |Stress| - 1

where: * 'Allowable' is the compressive buckling stress allowable * 'Stress' is the compressive stress (MS is not calculated in case of tensile stress), * 'MS' is the margin of safety

Allowable = eta * PI^2*ks*E/(12*(1-nu^2)) * (t/c)^2 where * 'ks' is the buckling coefficient * 'E' is the Young modulus * 'nu' is the elastic Poisson coefficient * 't' is the panel thickness * 'c' is the shorter panel dimension c = min(a,b) * 'eta' is the plasticity reduction factor: SigmaAllowablePlastic = eta*SigmaAllowableElastic * eta = 1 if material is considered as elastic (Material behaviour = Elastic) * eta is obtained from the MetallicPanelCompressivePlasticityCurveBC1 charts if material is considered as elastic-plastic (Material behaviour = Elastic-Plastic): * SigmaAllowablePlastic/Sigma0.7 = f(SigmaAllowableElastic/Sigma0.7) * Sigma0.7 is the stress for secant modulus equal to 70% of Young modulus

Input E Young modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Longer panel dimension b Shorter panel dimension t Panel thickness BC Type of support along edges r Panel radius of curvature behaviour Material behaviour nblc Number of load cases sigma Stress coming from load extraction Output sigmaAllowable Stress allowable MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Longer panel dimension b Shorter panel dimension t Panel thickness bc Type of support along the edges r Panel radius of curvature behaviour Material behaviour sigma Stress coming from load extraction ms Margin of safety sigmaAllowable Stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingFlatBending | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | beta, | ||

| double | t, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma1, | ||

| double[] | sigma2, | ||

| out double[] | ms, | ||

| out double[] | sigmaAllowable | ||

| ) |

MS Plate Buckling Flat Bending Computes margin of safety of a flat metallic rectangular panel under bending load

The formula is MS = sigmaAllowable / abs(sigma) - 1

where: * 'sigmaAllowable' is the bending buckling stress allowable * 'sigma' is the compressive stress at one edge of the panel, sigma = min( sigma1, sigma2 ) * 'MS' is the margin of safety

Allowable = eta * PI^2*kb*E/(12*(1-nu^2)) * (t/b)^2 where * 'kb' is the bending buckling stress coefficient * 'E' is the Young's modulus * 'nu' is the elastic Poisson coefficient * 't' is the panel thickness * 'a' is the unloaded edge length * 'b' is the loaded edge length * 'beta' Loading length ratio, the factor which, divided by b, gives the edge length in compression (while the remaining edge length is in tension). * 'beta' is calculated on the basis of sigma1 and sigma2 with an hypothesis of linear behaviour with the formula: * beta = (fc - ft) / fc where fc = min(sigma1, sigma2) and ft = max(sigma1, sigma2) ) * 'eta' is the plasticity reduction factor: SigmaAllowablePlastic = eta*SigmaAllowableElastic * eta = 1 if material is considered as elastic (Material behaviour = Elastic) * eta is obtain from following charts if material is considered as elastic-plastic (Material behaviour = Elastic-Plastic):

SigmaAllowablePlastic/Sigma0.7 = f(SigmaAllowableElastic/Sigma0.7)

MetallicPanelCompressivePlasticityCurveBC2 with Sigma0.7 is the stress for secant modulus equal to 70% of Young modulus Input E Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length beta Loading length ratio. If not specified (beta = NA), beta is computed t Panel thickness behaviour Material behaviour nblc Number of load cases sigma1 Stress XX Side1 sigma2 Stress XX Side2 Output sigmaAllowable Stress allowable MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length beta Loading length ratio t Panel thickness behaviour Material behaviour sigma1 Stress XX Side1 sigma2 Stress XX Side2 ms Margin of safety sigmaAllowable Stress allowables

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingFlatCompressive | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | t, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType | bcUnloaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bcLoaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma, | ||

| out double[] | ms, | ||

| out double | sigmaAllowable | ||

| ) |

MS Plate Buckling Flat Compressive Computes margin of safety of a flat metallic rectangular panel under compressive load

The formula is MS = sigmaAllowable / abs(sigma) - 1

where: * 'sigmaAllowable' is the compressive buckling stress allowable, * 'sigma' is the compressive stress (MS is not calculated in case of tensile stress), * 'MS' is the margin of safety

Allowable = eta * PI^2*kc*E/(12*(1-nu^2)) * (t/b)^2 where * 'kc' is the bending buckling stress coefficient * 'E' is the Young's modulus * 'nu' is the elastic Poisson coefficient * 't' is the panel thickness * 'a' is the unloaded edge length * 'b' is the loaded edge length * 'eta' is the plasticity reduction factor: SigmaAllowablePlastic = eta*SigmaAllowableElastic * eta = 1 if material is considered as elastic (Material behaviour = Elastic) * eta is obtain from following charts if material is considered as elastic-plastic (Material behaviour = Elastic-Plastic):

SigmaAllowablePlastic/Sigma0.7 = f(SigmaAllowableElastic/Sigma0.7) MetallicPanelCompressivePlasticityCurveBC1 if the Boundary Condition for the unloaded edges is Simply Supported-Free, MetallicPanelCompressivePlasticityCurveBC2 if the boundary condition for the unloaded edges is different of Simply Supported-Free

Input E Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness BC_Unloaded Type of support along unloaded edges {'Clamped-Clamped';'Simply Supported-Clamped';'Simply Supported-Simply Supported';'Free-Clamped';'Free-Simply Supported'} BC_Loaded Type of support along loaded edges {'Clamped';'Simply Supported'} behaviour Material behaviour nblc Number of load cases sigma Stress coming from load extractor Output sigmaAllowable Stress allowable MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness bcUnloaded Type of support along unloaded edges bcLoaded Type of support along loaded edges behaviour Material behaviour sigma Stress coming from load extractor ms Margin of safety sigmaAllowable Stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingFlatLongitudinalBendingCombined | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | t, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType | bcUnloaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bcLoaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma1, | ||

| double[] | sigma2, | ||

| out double[] | ms, | ||

| out double | sigmacr, | ||

| out double | sigmabcr | ||

| ) |

MS Plate Buckling Flat Longitudinal Bending Combined Computes margin of safety of a rectangular flat metallic panel in buckling under combined bending and longitudinal loads

This formula is derived from the interaction equation Rb ^ 1.75 + Rc = 1.0

where: * Rc = sigmac / sigmacr is the stress ratio due to compression stress, with: * sigmac is the given longitudinal stress * sigmacr is the compression stress allowable for buckling

* Rb = sigmab / sigmabcr is the stress ratio due to bending stress with * sigmab is the given compressive stress due to bending * sigmabcr is the bending stress allowable for buckling

Input E Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length beta Loading length ratio t Panel thickness BC_Unloaded Type of support along unloaded edges {'Clamped-Clamped';'Simply Supported-Clamped';'Simply Supported-Simply Supported';'Free-Clamped';'Free-Simply Supported'} BC_Loaded Type of support along loaded edges {'Clamped';'Simply Supported'} behaviour Material behaviour nblc Number of load cases sigma1 Stress XX Side1 sigma2 Stress XX Side2 Output sigmacr Compressive stress allowable sigmabcr Bending stress allowable MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness bcUnloaded Type of support along unloaded edges bcLoaded Type of support along loaded edges behaviour Material behaviour sigma1 Stress XX Side1 sigma2 Stress XX Side2 ms Margin of safety sigmacr Compressive stress allowable sigmabcr Bending stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingFlatLongitudinalShearCombined | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | t, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType | bcUnloaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bcLoaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma, | ||

| double[] | tau, | ||

| out double[] | ms, | ||

| out double | sigmacr, | ||

| out double | taucr | ||

| ) |

MS Plate Buckling Flat Longitudinal Shear Combined Computes margin of safety of a rectangular flat metallic panel in buckling under combined shear and longitudinal loads

Under longitudinal and shear loads, the interaction equation is: MS=2/(RL + sqrt(RL ^ 2 + 4 * RS ^ 2)

This formula is derived from the interaction equation RL+R2S=1.0 RL + RS ^ 2 = 1.0

where: * RL = sigma / sigmacr is the stress ratio due to longitudinal stress, with: * sigma is the given longitudinal stress * sigmacr is the compression stress allowable for buckling (sigmacr < 0, as consequence RL < 0 in tension) * RS = tau / taucr is the stress ratio due to shear stress with * tau is the given shear stress * taucr is the shear stress allowable for buckling (taucr and tau always positive)

The panel edges are either clamped or simply supported.

Input E Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness BC_Unloaded Type of support along unloaded edges {'Clamped-Clamped';'Simply Supported-Clamped';'Simply Supported-Simply Supported';'Free-Clamped';'Free-Simply Supported'} BC_Loaded Type of support along loaded edges {'Clamped';'Simply Supported'} behaviour Material behaviour {'Elastic'; 'Elastic-Plastic'} nblc Number of load cases sigma Stress XX tau Stress XY Output sigmacr Compressive stress allowable taucr Shear stress allowable MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness bcUnloaded Type of support along unloaded edges bcLoaded Type of support along loaded edges behaviour Material behaviour sigma Stress XX tau Stress XY ms Margin of safety sigmacr Compressive stress allowable taucr Shear stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingFlatShear | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | t, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bc, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma, | ||

| out double[] | ms, | ||

| out double | sigmaAllowable | ||

| ) |

MS Plate Buckling Flat Shear Computes margin of safety of a flat metallic rectangular panel under shear load

The formula is MS = sigmaAllowable / abs(sigma) - 1

where: * 'sigmaAllowable' is the shear buckling stress allowable, * 'sigma' is the compressive stress (MS is not calculated in case of tensile stress), * 'MS' is the margin of safety

Allowable = eta * PI^2*ks*E/(12*(1-nu^2)) * (t/b)^2 where * 'ks' is the bending buckling stress coefficient * 'E' is the Young's modulus * 'nu' is the elastic Poisson coefficient * 't' is the panel thickness * 'a' is the panel longer dimension * 'b' is panel shorter dimension * 'eta' is the plasticity reduction factor: SigmaAllowablePlastic = eta*SigmaAllowableElastic * eta = 1 if material is considered as elastic (Material behaviour = Elastic) * eta is obtain from following charts if material is considered as elastic-plastic (Material behaviour = Elastic-Plastic):

SigmaAllowablePlastic/Sigma0.7 = f(SigmaAllowableElastic/Sigma0.7) MetallicPanelCompressivePlasticityCurveBC1, Warning: in fact graph is fig C5.13 but it is C5.7 graph divided by 2

Input E Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Panel longer dimension b Panel shorter dimension t Panel thickness BC Type of support along the edges {'Clamped';'Simply Supported'} behaviour Material behaviour nblc Number of load cases sigma Stress coming from load extractor Output sigmaAllowable Stress allowable MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness bc Type of support along the edges behaviour Material behaviour sigma Stress coming from load extractor ms Margin of safety sigmaAllowable Stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsPlateBucklingFlatShearBendingCombined | ( | double | e, |

| double | nu, | ||

| double | n, | ||

| double | a, | ||

| double | b, | ||

| double | t, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.UnloadedEdgeSupportType | bcUnloaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.EdgeSupportType | bcLoaded, | ||

| NXOpen.CAE.AeroStructures.Author.ABB.MaterialBehaviour | behaviour, | ||

| double[] | sigma1, | ||

| double[] | sigma2, | ||

| double[] | tau, | ||

| out double[] | ms, | ||

| out double | sigmabcr, | ||

| out double | taucr | ||

| ) |

MS Plate Buckling Flat Shear Bending Combined Computes margin of safety of a rectangular flat metallic panel in buckling under combined bending and shear loads

Under longitudinal and shear loads, the interaction equation is: MS = 1 / sqrt(Rb ^ 2 + Rs ^ 2)

This formula is derived from the interaction equation Rb ^ 2 + Rs ^ 2 = 1.0

where: * Rb = sigmab / sigmabcr is the stress ratio due to bendoing stress with * sigmab is the given compressive stress due to bending * sigmabcr is the bending stress allowable for buckling * Rs = tau / taucr is the stress ratio due to shear stress with * tau is the given shear stress * taucr is the shear stress allowable for buckling (taucr and tau always positive)

Input E Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness BC_Unloaded Type of support along unloaded edges {'Clamped-Clamped';'Simply Supported-Clamped';'Simply Supported-Simply Supported';'Free-Clamped';'Free-Simply Supported'} BC_Loaded Type of support along loaded edges {'Clamped';'Simply Supported'} behaviour Material behaviour {'Elastic'; 'Elastic-Plastic'} nblc Number of load cases sigma1 Stress XX Side1 sigma2 Stress XX Side2 tau Stress XY Output taucr Shear stress allowable that takes into account compressive/tensile stress sigmabcr Bending stress allowable MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus nu Elastic Poisson coefficient n Ramberg-Osgood parameter a Unloaded edge length b Loaded edge length t Panel thickness bcUnloaded Type of support along unloaded edges bcLoaded Type of support along loaded edges behaviour Material behaviour sigma1 Stress XX Side 1 sigma2 Stress XX Side 2 tau Stress XY ms Margin of safety sigmabcr Bending stress allowable taucr Shear stress allowable

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsShearTearOut | ( | double | tauAllowable, |

| double | d, | ||

| double | t, | ||

| double | b, | ||

| double | factor, | ||

| double[] | iPExtracted, | ||

| out double[] | ms | ||

| ) |

MS Shear Tear Out Computes margin of shear tear out (due to bolt hole)

The formula is MS = PShearTearOutAllowable / P - 1 * 'PShearTearOutAllowable' is the shear tear out load allowable. PShearTearOutAllowable = tauAllowable * 2 * t * ( b - D / 2 ) * 'tauAllowable' is the material shear stress allowable. For instance, it could be Fsu. * 'D' is the hole diameter * 't' is the thickness * 'b' is the distance from hole center to edge of the plate * 'P' is the axial load. P = FactorLoad * PExtracted * FactorLoad is the ratio of load between extracted load 'PExtracted' and 'P' * PExtracted is the extracted load.

Input tauAllowable Material shear stress allowable D Diameter t Thickness b Edge distance Factor Load factor nblc Number of loadcases PExtracted(nblc) Axial load (extracted) Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

tauAllowable Material shear stress allowable d Diameter t Thickness b Edge distance factor Load factor iPExtracted Axial load (extracted) ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsTrescaPlaneStress | ( | double | fs, |

| double[] | fx, | ||

| double[] | fy, | ||

| double[] | fxy, | ||

| out double[] | ms | ||

| ) |

MS Tresca.

Computes margin of safety based on Tresca yield criterion under plane stress condition

The yield criteria of isotropic materials limit the elastic domain during loading. According to the Tresca criterion, yield failure is expected when the greatest shear stress reaches the shear strength of the material. Thus, the maximum shear stress yield criterion can be specified as 'max((|S1-S2|)/2 , (|S1-S3|)/2, (|S2-S3|)/2) <= (FS)/2' where * 'S1', 'S2' and 'S3' are the principal stresses. * 'FS' is the material shear strength allowable

A margin of safety can be derived from this formulation: 'MS = (FS) / (max(|S1-S2| , |S1-S3|, |S2-S3|)) - 1' that must be greater than 0.

In a plane stress configuration, principal stresses are computed as 'S1 = (FX + FY)/2 + sqrt(((FX-FY)/2)^2 + FXY^2)' 'S2 = (FX + FY)/2 - sqrt(((FX-FY)/2)^2 + FXY^2)' where * 'FX' the normal stress in the X direction * 'FY' the normal stress in the Y direction * 'FXY' the shearing stress

Input FS Material shear strength allowable nblc Number of load cases FX Normal stress in the X direction FY Normal stress in the Z direction FXY Shear stress Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

fs Material shear strength allowable fx Normal stress in the X direction fy Normal stress in the Z direction fxy Shear stress ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.MsTsaiHillPlaneStress | ( | double | matFcL, |

| double | matFcLT, | ||

| double | matFtL, | ||

| double | matFtLT, | ||

| double | matFS, | ||

| double[] | fl, | ||

| double[] | flt, | ||

| double[] | fs, | ||

| out double[] | ms | ||

| ) |

MS Tsai-Hill Computes margin of safety on the basis of Tsai-Hill failure theory (plane stresses hypothesis)

The formula based on yield material allowables is 'MS=1-sqrt(((F_L)/FtcyL)^2+(FLT/FtcyLT)^2-((F_LF_(LT))/(FtcyLFtcyL))+(F_(S)/Fsy)^2)' where: * L and LT are material directions: 'Longitudinal' and 'Longitudinal' 'Transverse'. * 'F_L','FLT' and 'FS' are plane stresses. They are expressed under material direction (with 'S' for shear). * 'F(tc)yL', 'F(tc)yLT' and 'Fsy' are yield material stress allowables. 'tc' is for 'tensile' or 'compressive' properties. Choices are done depending on the type of the corresponding stresses ('F_L' and 'FLT').

The formula can also be based on failure material allowables. The formula is 'MS = 1 - sqrt ( (FL / F(tc)uL ) ^ 2 + ( FLT / F(tc)uLT ) ^ 2 - ( (FL * FLT) / ( F(tc)uL * F(tc)uL) ) + ( FS / Fsu ) ^ 2 )'

where: * 'F(tc)uL','F(tc)uLT' and 'Fsu' are ultimate material stress allowables.

Input Mat_FcL Material compressive stress, longitudinal direction Mat_FcLT Material compressive stress, long transverse direction Mat_FtL Material tensile stress, longitudinal direction Mat_FtLT Material tensile stress, long transverse direction Mat_FS Material shear stress nblc Number of load cases FL Stress(es), longitudinal direction FLT Stress(es), longitudinal transverse direction FS Shear stress(es) Output MS Margin of safety Return Status of the calculation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

matFcL Material compressive allowable, longitudinal direction matFcLT Material compressive allowable, long transverse direction matFtL Material tensile allowable, longitudinal direction matFtLT Material tensile allowable, long transverse direction matFS Material shear allowable fl Stresses, longitudinal direction flt Stresses, longitudinal transverse direction fs Shear stresses ms Margin of safety

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.SecantModulus | ( | double | e, |

| double | n, | ||

| double | fy, | ||

| double | sigma, | ||

| out double | iEs | ||

| ) |

Secant modulus Computes the secant modulus from material properties and stress.

The secant modulus ('Es') is defined as the stress('f') to strain ('epsilon') ratio at each value of stress.

The formula is 'Es = f / ( f / E + 0.002 * ( f / fy ) ^ n )' where: * 'f' is the stress * 'fy' is the yield stress * 'E' is the Young's modulus * 'n' is the Ramberg-Osgood parameter

The formula can be applied in compression and is 'Es = f / ( f / Ec + 0.002 * ( f / Fcy ) ^ nc)' where: * 'Fcy' is the compressive yield stress * 'Ec' is the compressive Young's modulus * 'nc' is the compressive Ramberg-Osgood parameter

Input E Young's modulus n Ramberg-Osgood parameter fy Yield stress sigma Stress Output Es Secant modulus Return Status of the computation

Created in NX12.0.0

License requirements: nx_masterfem ("Finite Element Modeling")

- Parameters

-

e Young's modulus n Ramberg-Osgood parameter fy Yield stress sigma Stress iEs Secant modulus

- Returns

| unsafe NXOpen.CAE.AeroStructures.Author.ABB.Status NXOpen.CAE.AeroStructures.Author.ABB.StressF07 | ( | double | iFy, |

| double | e, | ||

| double | n, | ||

| out double | f07 | ||

| ) |

Stress F0.

7 Computes the stress for secant modulus equal to 70% of Young's modulus.

The calculation is based upon the material properties. 'F0.7' is defined by: 'F0.7/epsilon=0.7E', where 'epsilon' is the strain, and 'E' is the Young's modulus. The formula can be applied for tensile and compressive stress, hence: 'F0.7 = ( (1/0.7 - 1) / 0.002 * Fty ^ n / E ) ^ ( 1 / ( n - 1 ) )' for tension, and 'F0.7c = ( ( 1 / 0.7 - 1 ) / 0.002 * Fcy ^ nc / Ec ) ^ ( 1 / ( nc - 1 ) )' for compression.